Trunnion mounted ball valve are widely used in various industries owing to their distinctive advantages.

One key advantage of trunnion ball valve is their excellent sealing performance. The trunnion design ensures a secure and reliable seal between the ball and seats, effectively preventing leakage even under high-pressure conditions. This feature is particularly crucial in applications where leak-tightness is of utmost importance, such as oil and gas pipelines and chemical plants.

Furthermore, trunnion mounted ball valves offer superior durability and resistance to wear. The trunnion arrangement provides additional support to the ball, reducing the load on the seats and minimizing the risk of deformation. This design allows for smooth and consistent operation, ensuring a longer service life and reducing maintenance requirements.

Additionally, trunnion valve provide exceptional flow control capabilities. The low torque required for operation allows for precise and effortless regulation of flow rates. The smooth rotation of the ball enables minimal pressure drop and turbulence, resulting in efficient and accurate flow control.

One key advantage of trunnion ball valve is their excellent sealing performance. The trunnion design ensures a secure and reliable seal between the ball and seats, effectively preventing leakage even under high-pressure conditions. This feature is particularly crucial in applications where leak-tightness is of utmost importance, such as oil and gas pipelines and chemical plants.

Furthermore, trunnion mounted ball valves offer superior durability and resistance to wear. The trunnion arrangement provides additional support to the ball, reducing the load on the seats and minimizing the risk of deformation. This design allows for smooth and consistent operation, ensuring a longer service life and reducing maintenance requirements.

Additionally, trunnion valve provide exceptional flow control capabilities. The low torque required for operation allows for precise and effortless regulation of flow rates. The smooth rotation of the ball enables minimal pressure drop and turbulence, resulting in efficient and accurate flow control.

-

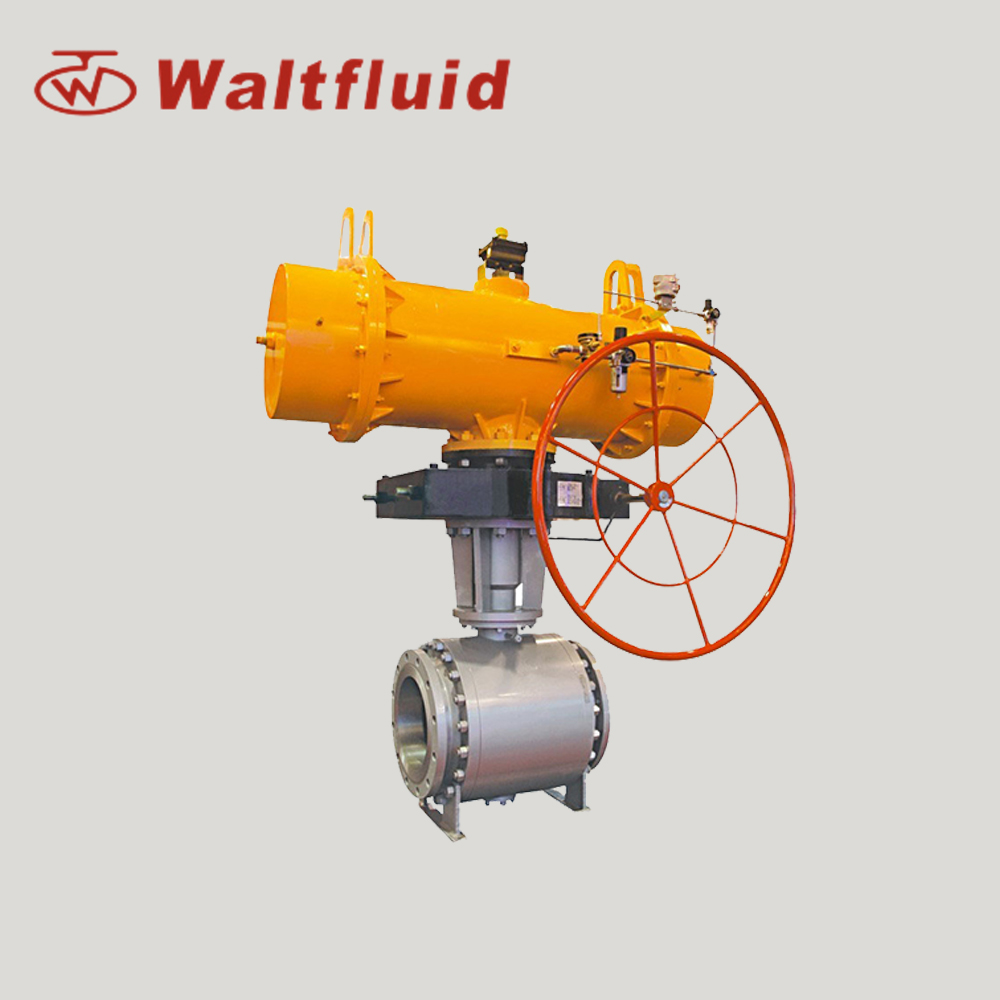

Trunnion Mounted Ball valve

Body Material:A105 / F304 / F316

Size :2”-40”

Seat Ring:PTFE / RTFE / DEVLON / PEEK

Pressure Rating: Class 150 / 300 / 600 / 900 / 1500

Valve Design :ASME B16.34 / API 6D

Connection : ASME B16.5 RF Flange end

ASME B16.5 RTJ Flange end

( Finished surface 125 ~ 250 AARH )Face to Face: ASME B16.10 / API 6D

Valve Test: API 598